Zero Waste Shipping Container

A major retail partner came to us asking to expand their recycling solutions to over 12 unique waste streams. They had a few in store collection units, but wanted something that would be a landmark, a statement, and a one-stop shop.

Early ideas looked at creating a structure outdoors to act as a permanent installation, but permitting issues prevented us from pursuing the idea, especially given that the partner wanted to run this as a pilot.

How do you create a solution that’s mobile and substantial? You use a recycled shipping container of course.

The Early Days

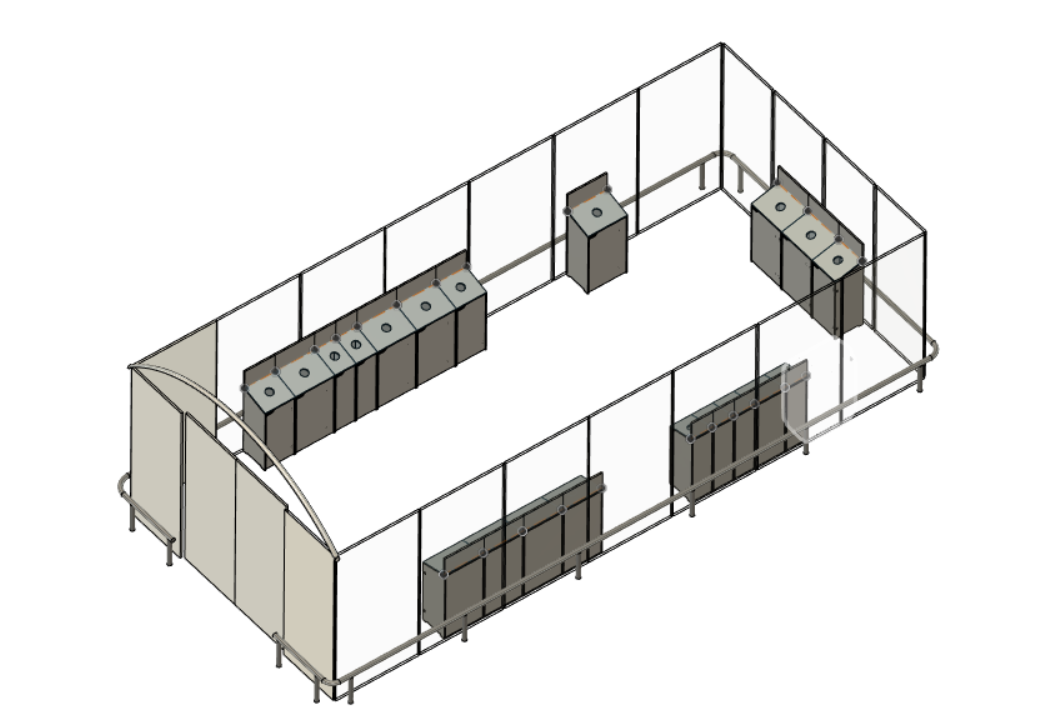

Early renditions of the hub were focused around a green-house-like structure with multiple collection kiosks that could be moved in and out as brand-sponsors changed.

Immediately this design ran into issues with permitting since it was a permanent structure that people could enter.

The design would have to be scrapped in exchange for something more mobile.

A New Direction

Inspiration came from finding a decommissioned shipping container turned into a mobile bar. Immediately the design pivoted into something much more temporary and with an added recycled feature.

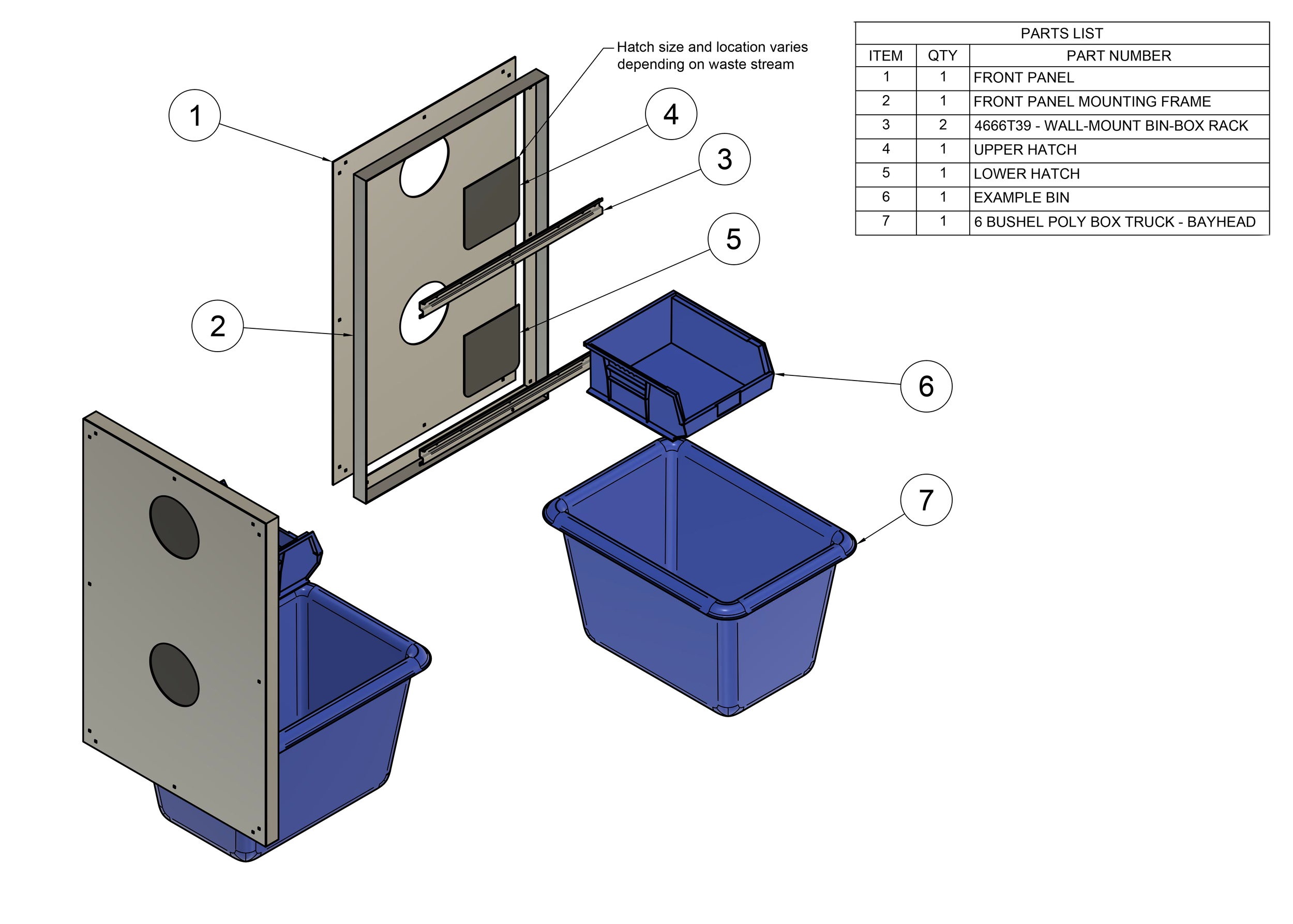

Heavy amounts of time was invested looking into the various mechanisms that would make up the hub, making sure to pick solutions that focused on safety and security within the hub.

Ample time was spent at this point anticipating how much of each waste stream would be collected and how to make it as simple to understand as possible. Ultimately the design landed on using color blocks and 3 different shapes and sizes of holes to guide users.

Quick Iterations

With an impending deadline, tweaks were focused on some value engineering and safety measures. The remainder of the effort before production was spent dialing in the branding, and consumer information, helping to inform them of the process, and the steps Walmart was taking

Straight to Production

After much deliberation, the final print files were approved and production with a partnering company in Colorado who build similar structures all the time began for the initial 3 hubs and moved quickly.

Prelaunch

In an unbelievable amount of time the 3 hubs were completed and I flew out for an in-person inspection. A few quick changes put them in great standing for launch

Install

With the final tweaks set the hubs were quickly loaded and sent off to their individual locales for the 6 month pilot run! It took a bit for the word to spread, but once it did collections quickly rose.

Towards the end of the pilot each hub was collecting 500 lbs of waste each, and continuing to run with 93% favorability and over a 60% return rate for customers, greatly helping Walmart and promoting a new recycling mission!

Moving On

With the pilot running successfully for a few months (including lasting through the occasional tornado) it was time to set the sights on optimizing and scaleability. I quickly began looking at ways to reduce cost, improve durability, and improve production speed while simultaneously adding the ability to swap panels in case we onboarded greater or fewer brand sponsors.

Sketches looked at different internal collection bins, minimizing exterior flat surfaces and vinyl treatments, alternate door styles for fewer breakable parts, and waste storage for between pickups.

Combining several solutions together resulted in the V2 design (see above and to the right) which features smaller, swappable panels that are held on by bolts. This allows the panels to be changeable with changing waste-streams and brand sponsors, and minimizes production labor and vinyl usage.

It also features multiple entryways on each panel for greater number of brand partners and a bin rail system to keep things hyper adjustable.

The design progress is ongoing as the pilot continues, but is aiming to reach the next stage by 2023